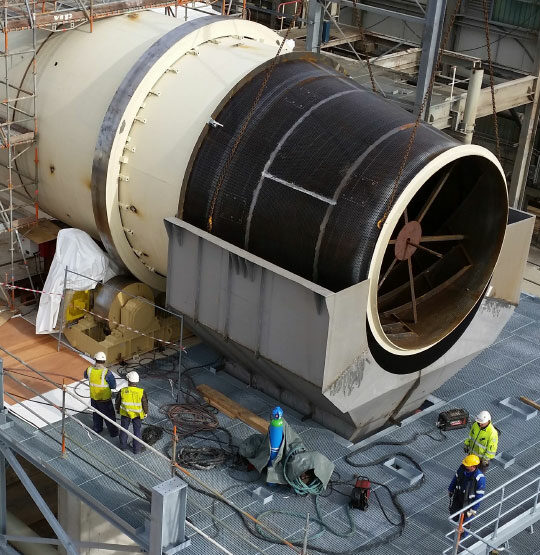

Nous vous proposons une gamme complète de services et d’équipements industriels depuis plus de 180 ans. Que ce soit dans le cadre d’une offre globale ou d’une prestation plus spécifique. Nous concevons, fabriquons, livrons, assemblons, supervisons / contrôlons et assistons nos clients.

Maguin a su développer son expertise et son savoir-faire dans différents secteurs d’activité. Aujourd’hui, la société Maguin propose une gamme complète de procédés et d’équipements industriels de la conception à la mise en route en assurant le service après-vente et la maintenance de nos équipements.

Maguin

2, rue Pierre Sémard

02800 CHARMES

France

Maguin-Chelmza

UI Bydgoska 4

CHELMZA 87-140

Pologne

Au service de toutes vos industries

où que vous soyez

dans le monde !

Maguin est une marque du Groupe Moret Industries